How is Nitrogen Used in Additive Manufacturing?

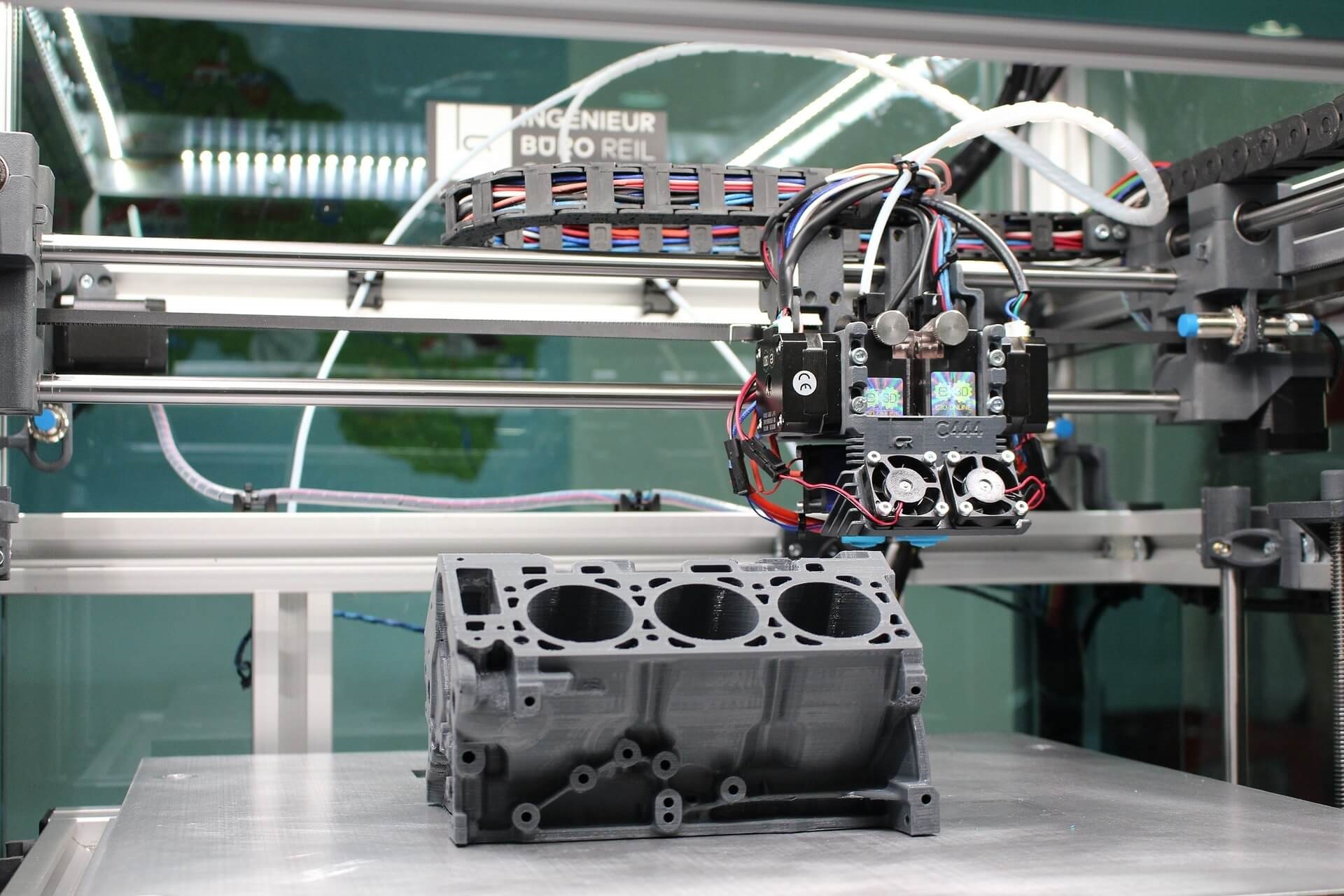

Additive Manufacturing, also known as 3D printing, is the process of creating products by adding different layers of material on top of one another. To begin, a 3D model is created using computer-aided design (CAD) software. When the sketch is finished, the additive manufacturing equipment will then begin layering the material, one on top of the other, until the 3D model has been created. A range of products can be used to create your product like different metals, plastics, and composite materials.

Additive Manufacturing application is limitless and used across many business sectors like medical, dental, automotive, and fashion. Additive Manufacturing offers unique solutions for companies because it provides the ability to create prototypes and customized solutions for niche markets.

Why is nitrogen used in Additive Manufacturing?

In the Additive Manufacturing industry, the prototype is created using selective laser machines. When manufacturing products, facilities need to limit the level of oxygen exposure because it can cause a number of issues like discoloration, formation of oxide layers, and impact the quality of the finishing and material wetting. When using nitrogen for additive manufacturing, you are able to maintain an inert environment and to reduce the rate of oxygen when nitrogen is added in the blanketing phase.

Peak Gas Generation's i-Flow PSA nitrogen generator eliminates the need for bulk nitrogen gas delivery and provides you with a sustainable, on-site nitrogen gas generation system that will deliver massive efficiency and cost savings in the long run. The i-Flow nitrogen generator uses PSA technology and is capable of producing a continuous supply of nitrogen gas to meet the demands of industrial manufacturing and processing applications, even if demands grow.

i-Flow can be tailored to your individual needs through its variable purity and flow rates which ensures your specific facility demands are met. Additionally, the system is modular and scalable. Instead of needing to purchase a new system or needing to increase the frequency of your cylinder deliveries if your demand increases, more columns can be added to i-Flow which makes this system future-proof. You can even remove columns should you have lower demand based on seasonal/variable demand. Your ever-changing needs will always be accounted for when you use i-Flow as your nitrogen gas generator.

To speak with one of our expert consultants regarding using i-Flow nitrogen for additive manufacturing, contact us.

i-Flow: Nitrogen Generators for Wine Production

Posted in all news on June 14 2018Companies operating in the highly competitive wine industry know that oxygen contamination and…

Read MoreWhat caused the CO2 shortage and how can you protect your supply chain in future?

Posted in all news on July 13 2018With CO2 being used extensively in the food and beverage industry there is a good chance that…

Read MoreSavings Calculator

Majority of industries buy nitrogen gas supplies via nitrogen cylinder packs, others meet their needs through liquid nitrogen dewars, micro-bulk tanks or bulk liquid nitrogen delivery. There is a better, more sustainable & safer option. Reduce the cost of nitrogen gas to your organisation & become self-sufficient. Find out how much you can save with a Peak nitrogen generator system.

- liquid/bottled N2Cost of liquid/bottled N2

- InvestmentInvestment cost

- TransportTransport cost

- ServiceService cost

- LeaseLease equipment

- EnvironmentalEnvironmental Tax

- EnergyEnergy cost